The cationic emulsion splitter is based on organic, biodegradable, tannins. It is widely used in food industry, providing a valuable oil / fat-phase and a low hydrocarbon contend in the water phase. No neutralization is required. In addition, it is working as a biological substitute for mineral coagulants like iron and aluminum salts, which are still used as a primary coagulant for the flocculation.

An environment friendly, PAM-free (Polyacrylamide-free) , anionic, biodegradable flocculant is added to remove the organic components of the blood. Additionally , the product will remove most of the charge of suspended mineral particles.

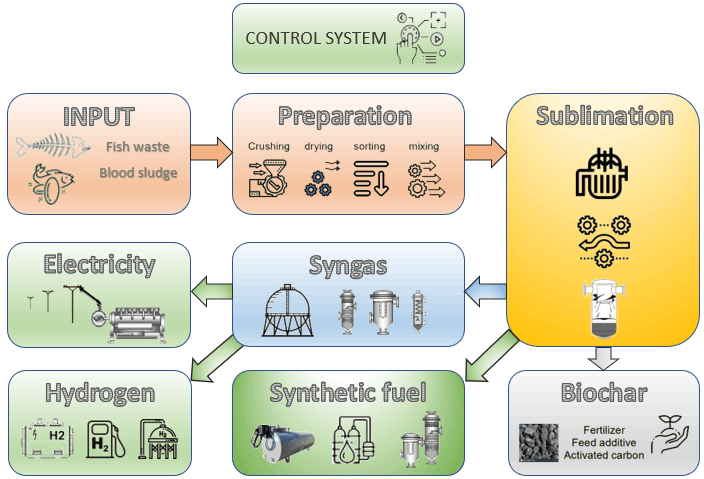

The separated fat and blood sludge is the energy source for the plant and thermal sterilization process.

BC Verfahrenstechnik (Process Engineering) uses advanced processes

to decompose various types of biomass (hydrocarbon waste).

Our refining plant distills useful end products such as diesel, methanol,

DMC, hydrogen, etc.

These end products can be sold or can be fed back into your factory

in the form of heat, cold or electricity.